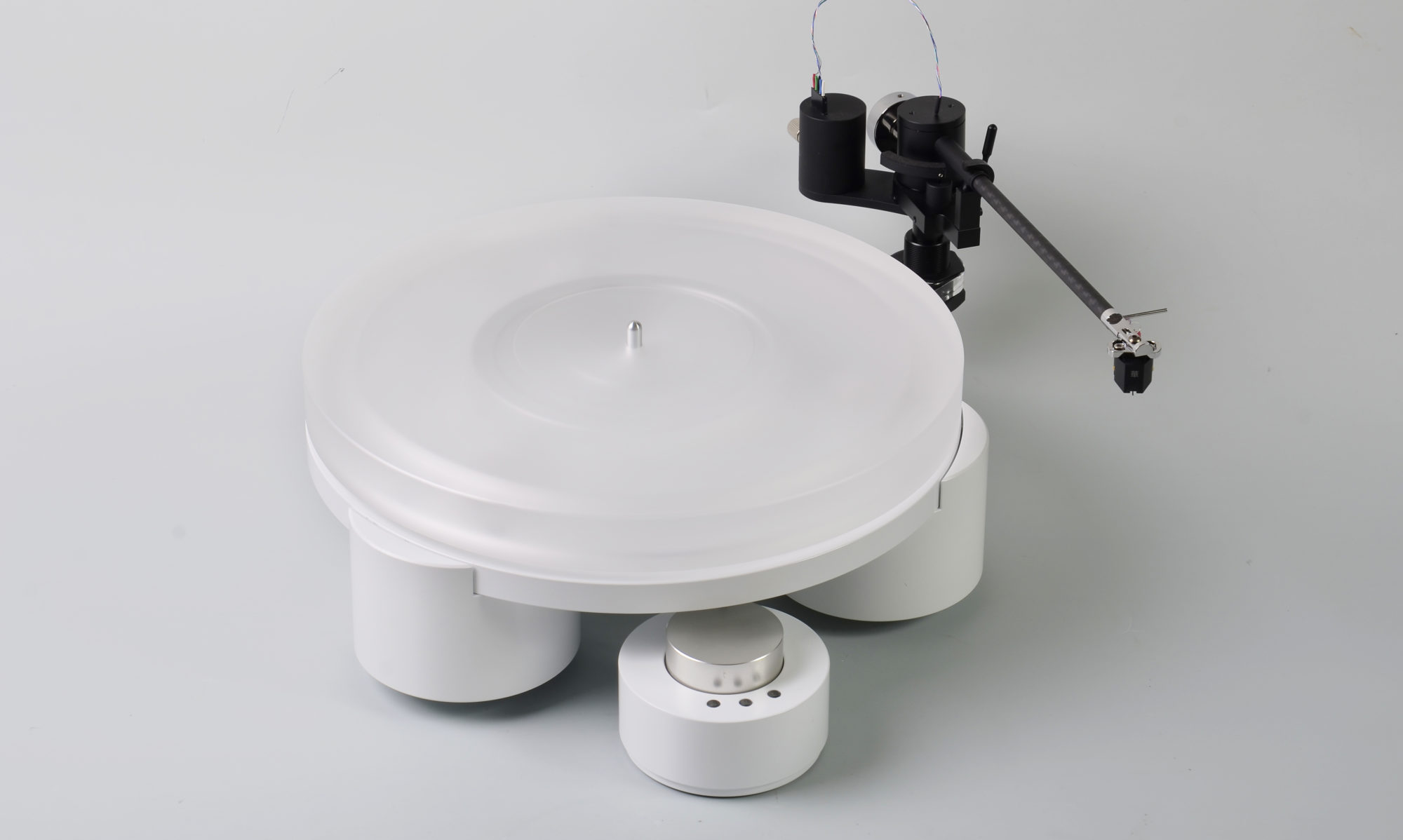

TT3 Turntable

1. Single belt drive turntable problem

A. For every turntable, the plater bearing must have a gap, size may vary, but in general the gap is needed for the plater bearing to rotate. In theory every player should have its dynamic balance so the plater bearing stays centered to reduce bearing noise or fiction. However, in reality it’s difficult to achieve due to problems in production or turntables wrongly set …etc Many factory choose to statically balance their plater, during rotation the bearing tilts as a single motor pulls from a different direction. This is the cause of noise problem for most belt drive turntables.

B. Another thing about single motor, The belt contact plater surface about 1/2 turn,If calculated with a tangent,belt quilts, (elasticity,tension, grip force) , after using a while, turntable drive belt getting old, belt getting lose, belt torn out. these will direct effect motor control turntable speed.

2. Turntable belt geometry

Typically for single motor Turntable, the belt contacts the plater surface for approximately 1/2 turn if calculated by tangent. The belt quality (elasticity, tension, grip force) deteriorates as time increase. Belt can turn old, get lose, torn, or wore out. These factors directly effect motor control of the turntable speed.

**But the relative choice of three motors, you must use a more quiet motor, so that the three motor noise is less than one motor.

3. Special suspension system

Magnetic bearing in the current turntable industry is not an innovative thing, but most of the magnetic turntable design uses magnetic bearing to reduce ball bearing pressure, this way it still can not reduce un-dynamic balance plater noise, the Uneven magnetic field in rotation plater will increase the noise.

Our turntables are also designed with magnetic bearing, but we are completely suspended, with specially designed belts which fixed bearing in the center of the sleeve, and via three-motors independent suspension system in 3D direction, the vibration come from out side will be eliminate or isolated .

The motor suspension system, also keep the belt tension constant, even with time the aging of the belt won’t change the rotation speed.

With a low residual energy of the acrylic light weight plater, keep the turntable unbalanced rotation under control, the bearing offsets the noise to a minimum.

4. Advance motor control system

TT3 turntable uses BLDC (Blush less Direct current) motor with low torque, by using a CPU to generate PWM signal to control server motor, unlike PLL circle, our control signal is more stable and will not drift easily. Can easy achieve 0.03% drift/mins( industrial stander is 0.3%)

5. DC power supply use over 22000 UF to make sure, DC voltage and current is stable

6. Precision POM Pulley cause less error for turntable speed.

7. The base of plinth is made of air craft Aluminium which is about 12KG , with 250 degree high temp powder coating. It can seal metal, also create a nature sound than bare metal. Besides the sound, you can choice different colour to match your interior or sound system.

8. Our turntable have full bass sound, you will find that it’s small but with powerful sound.

Features

- 3 motors spindle stabilize system

- 3 speeds (33 / 45 / 78 rpm)

- Light weight plater

- Special Upper suspension system

- Belt tension system

- DC tri-motor system with microchip speed control

- Can install 3 Tonearm

Specification

- Drive method : Three motors belt drive

- Motor : DC servo motor

- Speeds : 33 and 45 and 78 rpm

- Bearing : Magnet floatingwith ceramic shaft

- Platter : 1kg, Acrylic

- Tonearm support : Can install three tonearms

- Dimensions : 320 x 320 x 120MM

- Weight : 11kg